|

|

OZ ATV :: The Australian ATV Forum

Australia's Largest ATV Forum

|

|

|

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

Posted: Thu Dec 27, 2007 11:17 am Post subject: BC's tech info thread.(updated 25/4/08) Posted: Thu Dec 27, 2007 11:17 am Post subject: BC's tech info thread.(updated 25/4/08) |

|

|

Being a, "do it myself because I don't trust anyone else to do it the way I want it " kind of guy, or is that "too stupid to realize I can't ", I've spent many many hours chasing info and parts to keep my 250R going (occasionally). With this I have collected a whole heap of usefull and interesting info that is clogging up my hard drive so I thought I would start dumping it on here for all to use at their leisure. I'll put up bits and pieces when I can but if there is anything anyone is chasing let me know, I've probably stumbled across it at some time and I'll dig it up. BC

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425

Last edited by BC250R on Fri Apr 25, 2008 11:16 am; edited 2 times in total |

|

| |

|

|

|

|

|

|

|

|

Sponsor

|

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

Posted: Thu Dec 27, 2007 11:30 am Post subject: UNDERSTANDING SPARKPLUGS Posted: Thu Dec 27, 2007 11:30 am Post subject: UNDERSTANDING SPARKPLUGS |

|

|

UNDERSTANDING SPARKPLUGS

Here is some info I found on the NGK site that busts a few myths about plugs and gives a few pointers on gaps, heat range etc. Take note of the bit about what gap and why. Do you check yours?

1. Installing spark plugs

Torque is one of the most critical aspects of spark plug installation. Torque directly affects the spark plugs' ability to transfer heat out of the combustion chamber. A spark plug that is under-torqued will not be fully seated on the cylinder head, hence heat transfer will be slowed. This will tend to elevate combustion chamber temperatures to unsafe levels, and pre-ignition and detonation will usually follow. Serious engine damage is not far behind.

An over-torqed spark plug can suffer from severe stress to the Metal Shell which in turn can distort the spark plug's inner gas seals or even cause a hairline fracture to the spark plug's insulator...in either case, heat transfer can again be slowed and the above mentioned conditions can occur.

The spark plug holes must always be cleaned prior to installation, otherwise you may be torquing against dirt or debris and the spark plug may actually end up under-torqued, even though your torque wrench says otherwise. Of course, you should only install spark plugs in a cool engine, because metal expands when its hot and installation may prove difficult. Proper torque specs for ATC250R plug in alloy head is 2.5~3.5 kg/m

3. Gapping

Since the gap size has a direct affect on the spark plug's tip temperature and on the voltage necessary to ionise (light) the air/fuel mixture, careful attention is required. While it is a popular misconception that plugs are pre-gapped from the factory, the fact remains that the gap must be adjusted for the vehicle that the spark plug is intended for. Those with modified engines must remember that a modified engine with higher compression or forced induction will typically require a smaller gap settings (to ensure ignitability in these denser air/fuel mixtures). As a rule, the more power you are making, the smaller the gap you will need.

A spark plug's voltage requirement is directly proportionate to the gap size. The larger the gap, the more voltage is needed to bridge the gap. Most experienced tuners know that opening gaps up to present a larger spark to the air/fuel mixture maximises burn efficiency. It is for this reason that most racers add high power ignition systems. The added power allows them to open the gap yet still provide a strong spark.

With this mind, many think the larger the gap the better. In fact, some aftermarket ignition systems boast that their systems can tolerate gaps that are extreme. Be wary of such claims. In most cases, the largest gap you can run may still be smaller than you think.

4. Heat Range

With modified engines (those engines that have increased their compression) more heat is a by-product of the added power that normally comes with increased compression. In short, select one heat range colder for every 75-100 hp you add, or when you significantly raise compression. Also remember to retard the timing a little and to increase fuel enrichment and octane. These tips are critical when adding forced induction (turbos, superchargers or nitrous kits), and failure to address ALL of these areas will virtually guarantee engine damage.

An engine that has poor oil control can sometimes mask the symptom temporarily by running a slightly hotter spark plug. While this is a "Band-Aid" approach, it is one of the only examples of when and why one would select a hotter spark plug.

5. Using "racing" spark plugs

Be cautious! In reality, most "racing" spark plugs are just colder heat ranges of the street versions of the spark plug. They don't provide any more voltage to the spark plug tip! Their internal construction is no different (in NGK's case, as all of our spark plugs must conform to the same level of quality controls) than most standard spark plugs.

NGK as a company tries to stay clear of saying that a racing spark plug (or ANY spark plug) will give you large gains in horsepower. While certain spark plugs are better suited to certain applications (and we're happy to counsel you in the right direction) we try to tell people that are looking to "screw in" some cheap horsepower that, in most cases, spark plugs are not the answer.

To be blunt, when experienced tuners build race motors, they select their spark plugs for different reasons: to remove heat more efficiently, provide sufficient spark to completely light all the air/fuel mixture, to survive the added stresses placed upon a high performance engine's spark plugs, and to achieve optimum piston-to-plug clearance.

Some of these "specialised racing plugs" are made with precious metal alloy centre/ground electrodes or fine wire tips or retracted-nose insulators. Again, these features do not necessarily mean that the spark plug will allow the engine to make more power, but these features are what allow the spark plug to survive in these tortuous conditions. Most racers know screwing in a new set of spark plugs will not magically "unlock" hidden horsepower.

6. Using high power ignition systems

Many of the more popular aftermarket ignition systems are of the capacitive discharge type. They store voltage, or accumulate it, until a point at which a trigger signal allows release of this more powerful spark. Companies like Mallory, MSD, Crane and Accel, to name a few, offer such systems.

They affect spark plugs in that they allow the gaps to be opened up to take advantage of the increased capacity. The theory is that the larger and the more intense the spark you are able to present to the air/fuel mixture, the more likely you will be to burn more fuel, and hence the more power you will make.

We encourage the use of such systems, but only on modified or older non-computer controlled vehicles.

In reality, computer controlled vehicles do such a good job of lighting off the air/fuel mixture (as evidenced by the ultra-low emissions), added ignition capacity would do little to burn more fuel since the stock configuration is doing such a good job. Older non-computer controlled vehicles or those that have been modified with higher compression or boosted (nitrous, turbo, supercharged) engines can certainly take advantage of a more powerful ignition system.

more info at

http://www.ngkspark.com.au/tech_index.htm?http://www.ngkspark.com.au/pages/tech_content.htm

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425

Last edited by BC250R on Thu Dec 27, 2007 12:32 pm; edited 3 times in total |

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

Posted: Thu Dec 27, 2007 11:57 am Post subject: TUNING, JETTING AND PLUG CHOPS Posted: Thu Dec 27, 2007 11:57 am Post subject: TUNING, JETTING AND PLUG CHOPS |

|

|

TUNING, JETTING AND PLUG CHOPS

Here is some info from the MacDizzy website, this guy knows his 2 stroke stuff. He has so much info that he has recently had to recreate his web page and charge a minimal fee as it was busting the original server. Definitely woth a look.

http://macdizzy.com

The following is a response to question asked in regards to throttle response on a 250 2 stroke.

Quote:

The bike is currently in getting fresh top-end and I was thinking now would be the best time to try different jets. I am happy with the bike's performance, but I am looking for better response. The only real thing that I would complain about is that from slow speed the bike doesn't pick up or accelerate as what it probably could. It doesn't bog or die out, it just is kind of mediocre. Maybe I could get it crisper.

Answer:

By your description is sounds as if the slow(er) speed circuits could use some dialing in. Try my recommendation on determining pilot size, setting the airscrew and setting/adjusting idle speed. Itâs best to start at the bottom and work your way to the top. All jetting circuits overlap and will affect each other as you begin rejetting, so you need a good starting point. Time to start at the bottomâ¦

You need to make sure you have the correct pilot jet size and properly adjust your air screw before you try and set the idle. First you need to run the bike and bring it up to opperating temperature. Now find the airscrew. If you're looking at the carb from the left side of the bike it will be on the far right side just under the bell of the carb. Look for a small brass flat-head screw. Try adjusting it until you hear the idle come up. (If your bike doesn't idle try turning the idle speed up a little and resume this test.) You want to set your air screw at the point in which it idles the highest. If the idle get out of hand and takes off while adjusting the air screw then use your idle adjustment to keep it in check.

After this test ride the bike by getting the clutch out and putting along and then quickly roll the throttle on/wick it open. If it bogs and then takes off you're lean, turn the air screw IN (clockwise) an 1/8 of a turn and recheck. If its slow/sluggish to respond and then takes off you're rich, turn the air screw OUT (counter clockwise) an 1/8 of a turn and recheck. Keep doing this until you have achieved optimal throttle response.

After you've tuned for the best throttle response kill the bike and turn the air screw in until lightly seated making sure you count the number of turns it takes to get there. If you end up being more than 2.5 turns out on the air screw you'll want to try the next smaller pilot jet, less than 1 turn out and you'll need the next richer pilot.

If your pilot needs changed you'll have to repeat the process (start back at the top of this post) of setting the air screw. After all this if the idle is too high/low then you need to reset the idle screw.

Quote:

What would you do and what size jets would you recommend trying?? Btw, when I do a plug test, it usually comes out slightly oily.

Answer:

All bikes are not created equal so to say that xx jets will work in yy bike is usually far from true. Your best bet is to determine what is best for your bike in your environment under your variables.

Remember that a plug chop is only good for a few things like determining correct plug heat range, ignition timing and main jet strength. A plug chop needs to be performed on a brand new, properly gapped plug. When reading the plug it must be done on a new plug otherwise you're going off of multiple conditions with varying loads, conditions, and RPMs. How do you know what circuit/load/condition you're reading from? There are many variables. The weather, fuel, etc. are constantly changing and if you're trying to read a plug with weeks worth of changing information then you're shooting in the dark. You could have two out of four circuits messed up and still come out with a tan plug. The idea is to eliminate the variables and start fresh. ***Usually the fatter wire plugs (NGK BrxxES series) read faster and are cheaper which makes them ideal for a plug chop.***

As far as jetting is concerned, the plug is only useful in diagnosing the main jet strength. You need to look for the mixture ring, which will form at the very base of the insulator (way down behind the threaded portion of the plug). This will be hard to see unless you have a good magnifying glass and some good light or you cut the threaded portion away. You can't read main jet strength off the nose of the plug. If you install a new plug, warm it up, take it down the street and do a throttle chop the nose will still be white and like new, but the mixture ring will form at the base of the insulator.

But, weâre getting a little ahead of ourselves. Start at the bottom and work to the top, right? After the pilot/air screw/idle is sorted youâll want to move on to the needle and needle clip position. The best way to do this is the ride-and-feel method.

You need to start by marking your throttle housing with something you can write on. I like to use a strip of white medical tape and stick it on the throttle housing next to the grip. Now, go dig through your Mom's sewing supplies and find one of those needles with the colored head on it. Stick the needle into the big doughnut part of the grip next to where your thumb and forefinger contact the grip. Take a marker and draw a line on the tape next to where the needle sticks out of the grip, this mark will be "0" or closed throttle. Next, rotate the throttle all the way to WFO and make a mark on the tape where the needle sits. Obviously this mark will be WFO, WOT, full throttle, etc. Measure the distance between 0 and WFO and make a mark directly in the center for ½ throttle. Do the same for 1/8, ¼ and ¾ throttle. Now youâre set to do some roll-on throttle test to evaluate your needle/clip position.

Start at the bottom and work your way up by doing roll-on tests going from 1/8 to ¼, ¼ to ½, etc. Use the colored head on the needle and the marks you made on the tape for reference. Remember that a bog or a hesitation will indicate a lean condition while sluggish, slow to respond symptoms indicate that youâre rich. Sometimes itâs hard to distinguish between the two, so make a change going either richer or leaner and see if it helps or hurts the problem. Basic trial and error will be your best course of action until you better get the hang of things. Below is a chart to help guide you on what changes to make as you work your way through the circuits.

(Note that this chart is Keihin specific and the Mikuni equivalent will vary slightly)

After youâve finished with that then itâs time to check the main jet. You can continue to use the ride-and-feel method or you can opt to do it with a plug chop. The ride-and-feel method consists of using that same trial and error methodology. Try swapping out main jets until you find the one that pulls the hardest and longest on top. After youâve found that magic jet, use the next size larger main jet. This will give you a little bit of insurance and help you avoid any major meltdowns.

If youâre going to do a plug chop remember to install a new, properly gapped plug and make sure your machine is up to operating temps before making any attempt. After youâve brought the bike up to operating temp jump on and find an open stretch that will lead you back to your tools. Run it through the gears until you stick it in 4th (or 5th). Start at the very bottom of the gear and then wick it WFO. Hold it until the top of the gear and then some (just a little) and then hit the kill switch. When you hit the kill switch remember to close the throttle at the same time and coast back to your tools. Remove the plug and inspect.

Here is a helpful chart that will guide you on what to look for after youâve done your plug chop.

I know Iâm probably forgetting a few things here and there, but this should be enough to get you started. One thing will never change though, and that isâ¦

AVOID DETONATION AT ALL COSTS!!!

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425

Last edited by BC250R on Thu Dec 27, 2007 12:36 pm; edited 4 times in total |

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

Posted: Thu Dec 27, 2007 12:20 pm Post subject: RUNNING IN YOUR NEW MOTOR Posted: Thu Dec 27, 2007 12:20 pm Post subject: RUNNING IN YOUR NEW MOTOR |

|

|

RUNNING IN YOUR NEW MOTOR

CT Racing in the US has this proceedure listed on their website as a recomended running in proceedure for new engines or new piston/bored & honed top end. I followed this after I rebuilt my engine, it takes quite a while but these guys know what they're doing so if it saves you some grief in the long run it's worth in i'm my books. (believe me i know grief  ) )

http://www.ctracing.com/

Janssen racing in the Us list almost the identical proceedure on their site.

http://www.janssenmotorsports.com/tech_articles.php?act=getonearticle&artid=8

Installation Instructions

Your cylinder has been sized to extract its maximum potential. Because it has been fitted with close tolerances, a very important break in procedure is required. This is critical to increase performance without sacrificing reliability. Follow these guidelines closely and use the checklist to ensure that break in is completed in full.

1. After receiving your cylinder from CT, inspect it for any freight damage, if there are any questions contact CT immediately.

2. With dish soap and hot water wash your cylinder and piston only , scrub the cylinder bore with a paper towel until the towel remains clean. Dry the parts immediately and spray the cylinder bore with a liberal amount of WD-40, use a dry paper towel to spread the oil evenly throughout the cylinder.

3. CT recommend that you install new reeds and a new wrist pin bearing at this time, donât leave anything to chance, if a part is possibly worn out then replace it now. If you have a Suzuki LT250 or 500 always change the wrist pin thrust washers, they have a history of breaking and can do major damage to your engine.

4. Put a couple of drops of 2 stroke oil on the wrist pin and pin bearing and install the piston. The arrow on the piston crown faces the exhaust port. If there is no arrow, the ring locating pins will face the intake port. Double check that the circlips are firmly seated in their grooves. Install the piston rings with the numbers up. The numbers are located at the ring end gap, be sure the ring end gaps are aligned with their respective anti-rotation pins.

5. Assemble the cylinder with new gaskets, do not use any type of gasket sealer. Do not put any more oil on the piston or cylinder, the WD-40 left in the bore is enough lubricant. Compress the rings with one hand as you slide the cylinder down onto the piston, look through the intake window to check the alignment of the ring end gaps over the pins, adjust the rings now with a small screwdriver as necessary. If the ring end gaps are not centered over the pins you may break the rings if you force the cylinder down, take your time. Torque the base nuts to the factory specs, install the head, torque the nuts to the factory specs.

6. Install the intake and exhaust systems with new gaskets, we suggest using orange high temp silicone on the exhaust flange. Install the water hoses and fill the cooling system with glycol based coolant mixed 50/50 with distilled water.

7. Install a NGK spark plug of the exact type recommended by the factory.

8. Install a new Dura-Blue air filter for maximum engine life.

9. Richen the jetting in the carburetor, up two sizes on the main jet and one clip position on the needle.

10. CT cylinder kits are set up for 100 octane race gas, fill your tank accordingly. A mixture of 50/50- 110 octane racing gas and 92 octane pump gas will generally be fine for all CT engine kits unless other arrangements were made.

11. If you received a complete engine from CT it was shipped with no oil, check your gearbox or crankcase and fill it as necessary.

Break In Procedures

1. Start your engine and let idle occasionally blipping the throttle for four to five minutes. Allow the engine to cool completely. Repeat this "heat cycle" process four more times.

2. Warm up the engine again and ride the bike for five to seven minutes at a very easy pace, vary the rpm, donât ride at one speed. Donât ride at more than 1/3 throttle or more than 1/3 rpm. Let the engine cool down completely and repeat the initial break in ride. Let the engine cool down.

3. Check the base nuts and head nuts for proper torque, check the coolant level and add coolant as necessary.

4. Ride the bike for five to ten minutes at a moderate pace, vary the rpm, donât ride at more than 3/4 throttle or more than 3/4 rpm. Let the engine cool completely and repeat this secondary break in twice more.

5. Replace the spark plug with a new one. Ride the bike for five to eight minutes at a moderate pace, vary the rpm and shift up and down the gears. Once the engine is up to operating temperature you can make a jetting pass. Start in second gear and ride at full throttle through fourth gear, fully revving out fourth gear. With the throttle wide open in fourth hold the kill button down, pull in the clutch and stop. This is called a "plug chop"

6. Read the spark plug. With a pocket flashlight and a magnifying glass look at the porcelain part of the plug only, as you view the plug from the center electrode look down the length of the porcelain to its base, at this point there should be a dark chocolate colored smoke ring. There was not sufficient time to thoroughly color the whole plug, so the nose of the insulator may still be white, as long as there is a visible dark ring at the base everything is OK. Remember we want break in jetting so the plug should read rich/dark. Richen the jetting as necessary. If your having a hard time reading the spark plug, after the jet pass put the plug in a vice and hacksaw around the plug at the washer. Break the threads off with vise-grips, and the porcelain will be easy to read.

7. Complete the break in by riding at an aggressive pace for fifteen minutes, vary the rpm and donât cruise at part throttle, ride hard without revving the engine too high. At the end of this final break in session do another jetting pass/plug chop as described above. Check the spark plug for the correct dark/rich condition. Wiseco Piston equipped engines will require another one or two break in cycles, ride at a recreational pace not revving the engine hard, full throttle should only be used for very short periods, fifth and sixth gear should only be used to cruise, ride one tank of gas through the engine in this manner to complete the break in. We feel it take about two gallons of gas to break in a motor equipped with a cast piston and five gallons for a motor equipped with a Wiseco.

8. Replace the spark plug with a new one, ride the bike aggressively for eight minutes and do a jetting pass/ plug chop in fifth gear. If the porcelain color is still dark/rich, lean the main jet size one at a time until the smoke ring at the base of the porcelain is a light brown. If the porcelain base is white, donât run the engine and contact CT. If the plug color looks good, continue riding at a race pace for ten minutes. Stop and let the engine cool. Check the torque on the cylinder base and head nuts.

9. More on jetting. If you generally run your engine flat out in sixth gear then make your jet pass/ plug shop in sixth. Motocross jetting is checked in fifth gear, therefore it is not safe to run MX jetting in the desert or down a road wide open in top gear. Desert jetting is richer than MX jetting. When running an engine at full throttle for extended periods be sure to chop the throttle decisively to slow down, just rolling out a little can seize a well jetted engine.

CT racing 11805 E. Slauson Ave. Santa Fe Springs, Ca. 90670 ph. 562.945.2453 fx. 562.945.7006

[/b]

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425

Last edited by BC250R on Thu Dec 27, 2007 12:36 pm; edited 1 time in total |

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

Posted: Thu Dec 27, 2007 12:31 pm Post subject: THE LONG ROD ENGINE Posted: Thu Dec 27, 2007 12:31 pm Post subject: THE LONG ROD ENGINE |

|

|

THE LONG ROD ENGINE

More MacDizzy info for you. This explains what a lonf rod engine is, advantages and disadvantages etc. I built my motor as a long rod after reading this mianly for the reduces wear factor.

http://macdizzy.com

Long Rod-

How Long To Dwell

The 1987 and later TRX 250R's come equipped with a crankshaft that has a connecting rod that is 5 mm longer (center to center) than their earlier model cousins (1985 & 1986 ATC250R & 1986 TRX250R & the 1984 thru current model CR 250R). The piston of the long rod version engine has its wrist pin located 5 mm higher to offset it. A long rod crank used in combination with the short rod piston will bolt up - along with a base plate spacer if you want to increase the crankcase volume and take advantage of the longer rods leverage. In addition to this - because of the extra thickness the base plate spacer adds, it is necessary to buy longer cylinder base studs and install them. Many people use the longer studs from late model CR250's. This seems to be a popular conversion especially among those who are looking a wider power spread. When used with substancially increased displacement top ends (Pro-X and 265 cc to 275 cc modified stock TRX parts), the long rod may be favorable especially when used with the better breathing early model cylinder and piston.

It should be noted that though there is some benefit to this combination the longer rod also creates a longer dwell at TDC & BDC which decreases piston acceleration somewhat. Please click here to read more about it. The piston acceleration (answer taken from software) is 114864 ft/sec^2 with its 72 mm stroke using a 125.3 mm rod at 8300 RPM. If the rod is 130.3 mm instead, the number moves to 113880 ft/sec^2. When I did the calculation manually (ugh) I came up with slightly different numbers. I got 114623 ft/sec^2 for the 125.3 mm rod and 113669 ft/sec^2 for the 130.3 rod. It is interesting to note that even the latest model CR250 uses the same short rod as the early ATC & TRX 250R's.

The long rod crank can be used with the long rod piston, independent of the year model of the cylinder barrel - any year is ok -though there are some differences to later year model porting configurations. Generally the later model barrels have better porting on the exhaust side - the exhaust timing was more advanced and the front transfer ports are aimed better. There are some improvements in the squish thickness and area as well. Unfortunately, the intake recieved a case of the "restrictions" and the piston design changed to reflect its newly designed "improvement." Because of this new piston/cylinder design, wear on the intake side (thrust) of the barrel is reduced and piston life is extended though the barrels ability to breathe is somewhat impared. The long rod version has a wider, less "peaky" power delivery.

Though the overall power was about the same between the 2 versions, the short rod version revs more freely/quickly but it gives up some power spread. It may be of interest that most current 250cc motorcross engines use a rod length of 125mm (like the short rod TRX at 125.3). A longer connecting rod may be used to tune out some unfavorable characteristic of the engines power delivery. Perhaps where tuning by conventional means produces no favorable results - such as increased port timing - a longer rod may tame a peaky power delivery. Modifying the long rod version TRX cylinder/head to match the power output of the short rod version (using its pieces) proved to be difficult, time consuming and (nearly) impossible.

When combining the long rod and the 1986 piston the cylinder head-stay will have to be modified or removed since the cylinder will now be raised with the base plate spacer. If you decide to remove the head stay it is probably best to leave the tube connecting the frame rails together so it can still be used to stiffen the backbone of the frame as it was intended.

To reverse this design, use an 86 model year crankshaft with it's shorter rod and the 86 piston. This combination can be also used in any year model barrel. The connecting rods (125.3 mm and 130.3 mm) and main bearings are available individually for replacement and are much cheaper than the purchase of a complete new crankshaft.

The 86 style piston has a large cut out in its intake to allow for a lot of intake timing. There really is no need for an additional hole in it. Compared to the small hole on the later model pistons - the cut out of the 86 is huge. The only reason to use the 86 piston is to make up for the base plate spacer which is used on (later model) long rod motors to increase crankcase volume. The later model year pistons last longer because they have more skirt to them and their barrels have additional intake bridges to support them better.

Rick

Driving Impressions

I am fortunate enough to be able to sample both versions of the TRX motor almost every time I go riding. When my TRX was only a couple of years old (1988), its modifications were a 36 mm PJ carb, FMF "rev" pipe, cleaned up porting and stock 13/39 gearing. I performed identical modifications to a friends newer TRX cylinder (1988 model year - long rod). He had the same (model) pipe but did not have the larger carb. It was running its stock gearing (13/3 . We both had the same Ohtsu radials. . We both had the same Ohtsu radials.

While drag racing on a dry lake bed outside of San Filepe, Mexico it became clear that my TRX was the faster of the two. In fact time after time I would win by several bike lengths. We had another friend signal our start by using his arm in a rhythmic motion (and a 1, and a 2, and a 3...). We were both starting out in 2nd from a stop and would race until we reached maximum RPM in top gear (as fast as they would go). Traction was not a problem.

When we switched bikes and raced some more, again I won. Time after time by several bike lengths - about the same distance as when I was riding my bike. Our body weight was not much different. It may have been that I could feel the traction better. I would not rev "over" a gear or let it fall too far behind the gear when upshifting. The overall difference is marginal when drag racing.

[/u][/b]

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425 |

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

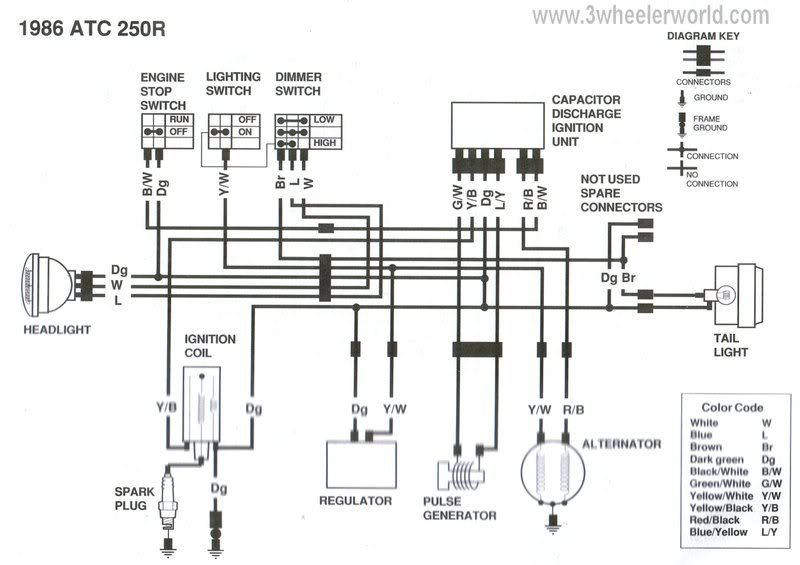

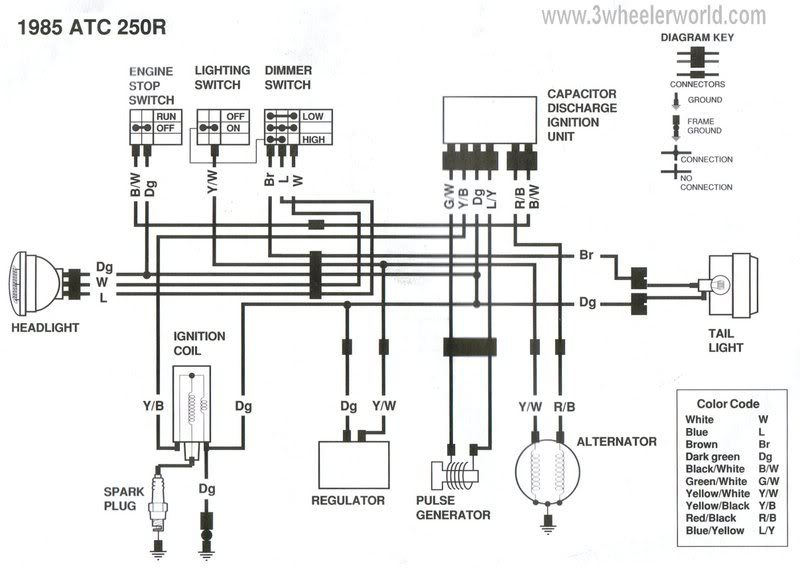

Posted: Thu Dec 27, 2007 12:53 pm Post subject: 250R WIRING DIAGRAMS Posted: Thu Dec 27, 2007 12:53 pm Post subject: 250R WIRING DIAGRAMS |

|

|

250R WIRING DIAGRAMS

Note that there is a difference between 85 and 86. It is mainly in the plug for the CDI

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425 |

|

| |

|

|

|

|

|

|

|

|

Aussieduner

Moderator

Joined: 05 Sep 2006

Posts: 1458

Location: New South Wales

|

Posted: Sat Dec 29, 2007 3:36 pm Post subject: Posted: Sat Dec 29, 2007 3:36 pm Post subject: |

|

|

This is an extremely useful thread Brett,nice work, now sticky !

_________________

1989 TRX 250R |

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

|

| |

|

|

|

|

|

|

|

|

Aussieduner

Moderator

Joined: 05 Sep 2006

Posts: 1458

Location: New South Wales

|

Posted: Sat Jan 05, 2008 7:35 pm Post subject: Honda 250R HRC Short Track Kit Parts List Posted: Sat Jan 05, 2008 7:35 pm Post subject: Honda 250R HRC Short Track Kit Parts List |

|

|

For those 250R HRC short track kit lovers, here's the list....

17510-HA2-810..............FUEL TANK

17620-MA0-000..............FUEL TANK CAP (DISCONTINUED)

19030-HA2-810..............RIGHT RADIATOR SHROUD

19035-HA2-810..............LEFT RADIATOR SHROUD

19045-HA2-810..............RIGHT RADIATOR GUARD COMP.

19046-HA2-810..............LEFT RADIATOR GUARD COMP.

19043-HA2-810..............RIGHT RADIATOR STAY

19044-HA2-810..............LEFT RADIATOR STAY

19047-HA2-810..............RADIATOR LOWER BRACKET (2 REQUIRED)

17509-HA2-811..............RIGHT SHROUD UPPER BRACKET

17512-HA2-811..............LEFT UPPPER SHROUD BRACKET

19062-HA2-810..............WATER HOSE B

19063-HA2-810..............WATER HOSE C

90556-044-000..............FRONT FENDER SETTING WASHER (6 REQ.)

19509-HA2-000.............COLLAR (2 REQ)

96000-06012-00............FLANGE SH 6x12mm BOLT (2 REQ)

53200-HA2-810..............STEERING STEM COMP.

_________________

1989 TRX 250R |

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

|

| |

|

|

|

|

|

|

|

|

BC250R

Joined: 23 Jan 2007

Posts: 375

Location: Stockton Dunes if i'm lucky

|

Posted: Fri Apr 25, 2008 9:27 am Post subject: Posted: Fri Apr 25, 2008 9:27 am Post subject: |

|

|

ESR GUIDE TO JETTING. BASED ON ENGINE AND CARBY SIZE

Recommended Jetting for a pipe and air box eliminator kit.

Note: this is a good starting point and has worked well for us at our altitude; (sea level)

however this is not set in stone and may vary.

Stock 34mm Keihin PJ

250-265cc

main 160-165

pilot 60

needle 4th clip

air screw 2 turns out

310-330

main 165-175

pilot 60

needle 4th clip

air screw 2 turns out

350 or bigger

we do not recommend the stock carburator

36-38 Keihin PJ

250-265cc

main 165-175

pilot 60

needle DGH 4th clip

air screw 2 turns out

310-330cc

main 172-178

pilot 60

needle DGH 4th clip

air screw 2 turns out

350-370cc

main 178-185

pilot 60

needle DGH 4th clip

air screw 2 turns out

38 and 39 Keihin PWK / Airstyker

250-265cc

main 172-178

pilot 50

needle DGH 4th clip

air screw 2 turns out

310-330

main 172-178

pilot 50

needle DGH 4th clip

air screw 2 turns out

350-370

main 178-185

pilot 50

needle DGH 4th clip

air screw 2 turns out

36 and 38 Mikuni TMX

250-265cc

main 360-400

pilot 25

needle 3rd clip

air screw 2 turns out

310-330cc

main 380-420

pilot 25

needle 3rd clip

air screw 2 turns out

350-370cc

main 420-460

pilot 25

needle 3rd clip

air screw 2 turns out

40.5mm Keihin PWK

250-310cc

this carburator is too big for this cc

330-350cc

main 178-185

pilot 50

needle DGH 4th clip

air screw 2 turns out

370cc

main 180-190

pilot 50

needle DGH 4th clip

air screw 2 turns out

There is also a list of jetting for people who need 4 wheels on the ESR site. Here's the link.

http://www.eddie-sanders-racing.com/oscmax/article_info.php?articles_id=2?osCsid=8b5b55e78965c7b5ac827ebb0369c047Pismo Beach therefore sea level like Stockton)

_________________

Technical info thread

http://www.ozatv.com/forum/viewtopic.php?t=4425 |

|

| |

|

|

|

|

|

|

|

|

atcmatt

4fiddy Racer

Joined: 26 Dec 2008

Posts: 207

Location: Sydney

|

Posted: Tue Nov 30, 2010 7:33 am Post subject: Posted: Tue Nov 30, 2010 7:33 am Post subject: |

|

|

when they reffer to the "4th clip" on your needle, is that from the top or the bottom?

_________________

1985 250es

1978 atc70 |

|

| |

|

|

|

|

|

|

|

|

ForeverThreeWheels

The Day Starts With OZATV !

Joined: 18 Nov 2008

Posts: 1742

Location: Maitland

|

Posted: Mon Jun 13, 2011 9:56 pm Post subject: Posted: Mon Jun 13, 2011 9:56 pm Post subject: |

|

|

| atcmatt wrote: | | when they reffer to the "4th clip" on your needle, is that from the top or the bottom? |

Bump for an answer...?

_________________

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

© 2001, 2002 phpBB Group

|

|

|